Contact Us Now! foreign_trade@0086pv.com

Contact Us Now! foreign_trade@0086pv.com

Product Category:BREATHER VALVE

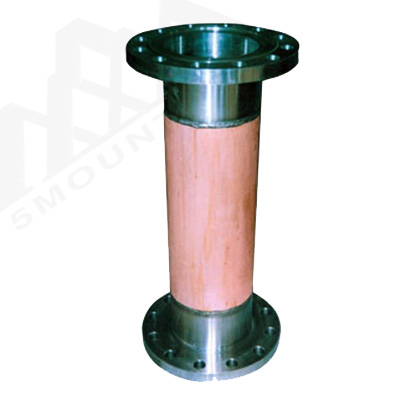

Product Name:FP oxygen flame arrestor

Product Tag:oxygen flame arrestor

Update Date:2021/8/31 0:00:29

Visits:

Oxygen flame arrestor (also known as fire arrester), the function of the flame arrestor is to prevent external flames from entering equipment and pipelines containing flammable and explosive gases or to prevent flames from spreading between equipment and pipelines. The flame arrestor is designed and manufactured using the principle of extinguishing due to heat loss when the flame passes through the narrow pores of the thermal conductor.

Main performance: 1. Qualified anti-explosion performance, 13 consecutive anti-explosion performance tests can prevent fire each time. 2. The burning resistance is qualified, and there is no tempering in the burning test for 1 hour. 3. The shell water pressure test is qualified. This product has a reasonable structure, light weight and corrosion resistance. Easy to check and repair, easy to install. The flame arrester core is made of stainless steel, which is corrosion-resistant and easy to clean.

Oxygen flame arrestor is the front and rear flame arrestor of oxygen pipeline valve, which is welded by special copper alloy and stainless steel.

The following is the working principle of oxygen flame arrester:

Most oxygen flame arresters are composed of many small, uniform or uneven channels or pores that can pass gas. These channels or pores are required to be as small as possible, as long as they can pass through the flame. In this way, after the flame enters the flame arrester, it is divided into many small flame streams and extinguished. The mechanism by which the flame can be extinguished is heat transfer and wall effect.

(1) Heat transfer

One of the factors that an oxygen flame arrestor can prevent the flame from spreading and force the flame to extinguish is heat transfer. The flame arrestor is composed of many small passages or pores. When the flame enters these small passages, many small flame streams are formed. Due to the large heat transfer area of the channel or pore, after the flame passes through the channel wall for heat exchange, the temperature drops, and the flame is extinguished to a certain extent. Tests show that when the thermal conductivity of the flame arrester material is increased 460 times, its extinguishing diameter only changes 2.6%. This shows that the material problem is secondary. That is, heat transfer is a reason for extinguishing the flame, but it is not the main reason. However, the mechanical strength and corrosion resistance should be considered when selecting materials.

(2) Wall effect

According to the theory of the chain reaction of combustion and explosion, it is believed that the phenomenon of combustion and explosion is not the result of direct interaction between molecules, but is excited by external energy (heat energy, radiation energy, electrical energy, chemical reaction energy, etc.) that causes molecules to split into very active and reactive energy. Free radicals with short life span. Chemical reactions are carried out by these free radicals. Free radicals interact with another molecule, and the result of the action can produce new free radicals in addition to the product. In this way, free radicals are consumed and reproduced in such a cycle. It can be seen that the condition for self-combustion of flammable mixed gas (without the effect of external energy after the start of combustion) is: the number of newly generated free radicals is equal to or greater than the number of free radicals that disappear. Of course, self-burning is related to the conditions of the reaction system, such as temperature, pressure, gas concentration, container size and material, etc. As the size of the flame arrestor channel decreases, the collision probability between free radicals and reactive molecules decreases, while the collision probability between free radicals and the channel wall increases, which promotes the reduction of free radical reactions. When the channel size is reduced to a certain value, this wall effect creates the condition that the flame cannot continue, and the flame is prevented. It can be seen that the wall effect is the main mechanism for the flame arrestor to stop the flame. Starting from this point, a flame arrestor with a known structure can be designed to meet industrial needs.

1. Overview of FP oxygen flame arrestor:

The FP-XT oxygen pipeline flame arrester and the FPV-XT oxygen pipeline valve front and rear flame arresters are welded with special copper alloy and stainless steel. It can effectively prevent the "adiabatic compression" that is easy to form when the oxygen pipeline valve is suddenly opened, and the local temperature rises sharply, becoming an ignition source; it can prevent high-speed moving material particles (such as rust, dust, welding Slag, etc.) friction and collision with the pipe behind the valve will generate sparks and become ignition energy. The use of flame arrestor can quickly block the fire source and prevent the occurrence of explosion accidents in the pipeline.

2. Purpose of FP oxygen flame arrestor:

This product is widely used in oxygen transmission pipelines in metallurgy, chemical and other industries. It can effectively cut off the fire source caused by the rapid friction between the debris in the high-speed airflow and the pipe wall, and prevent the occurrence of pipeline explosion accidents. The user can directly weld this product to the appropriate part of the oxygen pipeline to operate. This flame arrestor is suitable for flame arresting oxygen pipelines with pipelines DN15-500mm and working pressure not greater than 3MPa. It has flange and internal thread connection.

________________________________________________________________________________________________________

Product Keyword Tags>>

Breather valve,Breather valve Manufacturer,Breather Valve Manufacturers in china