Contact Us Now! foreign_trade@0086pv.com

Contact Us Now! foreign_trade@0086pv.com

Product Category:BREATHER VALVE

Product Name:FPB gas flame arrester

Product Tag:gas flame arrester

Update Date:2021/8/30 23:59:20

Visits:

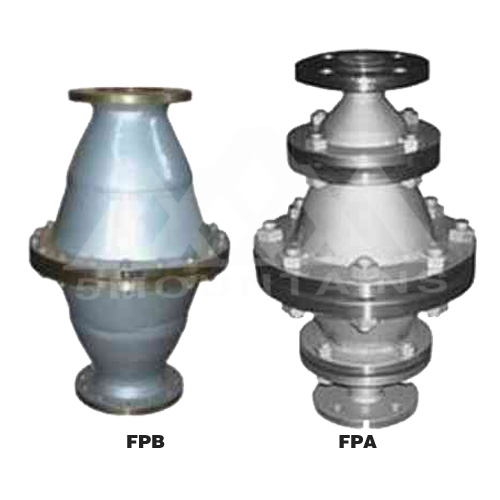

Gas flame arrestor (FPB type)

1. Product use:

The gas flame arrester is suitable for installation in the pipeline network that conveys combustible gas such as heating furnace fuel gas, natural gas, liquefied petroleum gas, coal mine gas, and also suitable for civil gas pipelines to prevent the flame from being reversed in the pipeline under abnormal conditions. To avoid catastrophic accidents.

2. Product features:

The gas flame arrestor is designed and manufactured using the principle of quenching the subsonic or supersonic flame propagating in the pipeline by using the gap between the metal corrugated discs. The connecting flange of the flame arrestor is designed and manufactured according to the HG20595-97 concave and convex surface. For the design and manufacture of butt-welded steel pipe flanges, users need to choose other standard connecting flanges. Please specify in the order. For gas flame arresters with PN>4.0MPa, our factory can also design and manufacture. The product structure diagram is as follows:

3. Installation and maintenance of flame arrestor:

The pipeline explosion-proof corrugated flame arrester can be installed horizontally or vertically to connect with the pipeline. Check regularly. Once blockage is found, use high-pressure steam, compressed air or organic solvent to clean it. If the core is found to be mechanically damaged or corroded by the medium, it should be replaced immediately.

1. In order to ensure that the performance of the flame arrestor meets the purpose of use, before installing the flame arrester, you must carefully read the instructions and carefully check whether the label is consistent with the requirements of the installed pipeline.

2. The flow direction mark on the flame arrester must be consistent with the flow direction of the medium.

3. Check once every six months. Check whether the fire barrier is blocked, deformed, or corroded.

4. The blocked fire barrier should be cleaned to ensure that each hole is unblocked, and the deformed or corroded fire barrier should be replaced.

5. When cleaning the core parts of the flame arrester, use high-pressure steam, non-corrosive solvent or compressed air to purge, and do not use sharp hardware scrubbing.

6. When re-installing the fire barrier, the gasket should be updated to confirm that the sealing surface is clean and undamaged, and no air leakage is allowed.

________________________________________________________________________________________________________

Product Keyword Tags>>

Breather valve,Breather valve Manufacturer,Breather Valve Manufacturers in china